...COMPLETE SUPPLY OF PRECISION MACHINED PARTS

MILLING TECHNOLOGY

TAJMAC-ZPS: MCFV 1680

- axis X,Y,Z : 1650 x 810 x 810 (mm)

- maximum table load: 2500 kg

- control system: Heidenhain

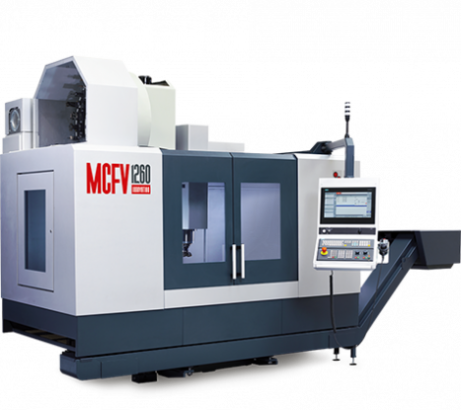

TAJMAC-ZPS: MCFV 1260 (2x)

- axis X,Y,Z : 1260 x 610 x 760 (mm)

- maximum table load: 1500 kg

- control system: Heidenhain

TURNING TECHNOLOGY

DOOSAN PUMA 3100 LY

- max. diameter of the bar: 102 mm

- max. diameter of the machining: 420 mm

- max. machining length: 1250 mm

- control system: Fanuc

DOOSAN PUMA 2600 Y (2x)

- max. diameter of the bar: 76 mm

- max. diameter of the machining: 365 mm

- max. machining length: 760 mm

- control system: Fanuc

DOOSAN Lynx 220 LYC + robot

- max. diameter of the bar: 51 mm

- max. diameter of the machining: 250 mm

- max. machining length: 510 mm

- control system: Fanuc

DOOSAN Lynx 220 LYC + robot

- max. diameter of the bar: 51 mm

- max. diameter of the machining: 250 mm

- max. machining length: 510 mm

- control system: Fanuc

3D MEASUREMENTS

DEA Global Performance 09.20.08

High precision portal 3D gauge.

- axis X,Y,Z : 900 x 2000 x 800 (mm)

- measuring volume: 1,440 m3.

- max. component weight: 1800 kg.

- measurement error: MPEe [μm] 1.8+L/333

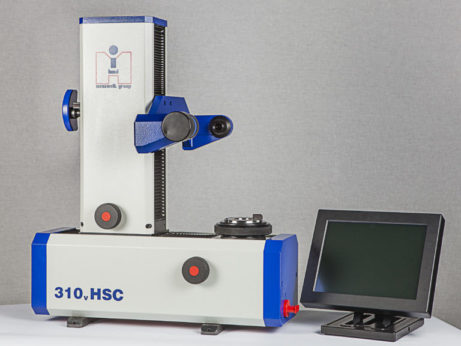

DEA Optiv Classic 443

Multisensor 3D measuring machine with high precision.

- axis X,Y,Z : 400 x 400 x 300 (mm)

- measuring volume: 0,048 m3.

- max. component weight: 30 kg.

- measurement error: MPEe [μm] 1.9+L/250

MARKING TECHNOLOGY

OTHER

SUBCONTRACTING ACTIVITIES